High-bypass turbofan engines

The low specific thrust/high bypass ratio turbofans used in today's civil jetliners (and some military transport aircraft) evolved from the high specific thrust/low bypass ratio turbofans used in such aircraft back in the 1960s.

Low specific thrust is achieved by replacing the multi-stage fan with a single stage unit. Unlike some military engines, modern civil turbofans do not have any stationary inlet guide vanes in front of the fan rotor. The fan is scaled to achieve the desired net thrust.

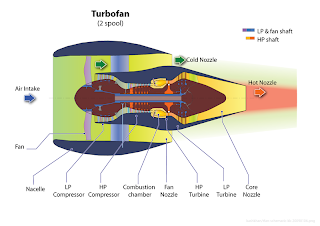

The core (or gas generator) of the engine must generate sufficient Core Power to at least drive the fan at its design flow and pressure ratio. Through improvements in turbine cooling/material technology, a higher (HP) turbine rotor inlet temperature can be used, thus facilitating a smaller (and lighter) core and (potentially) improving the core thermal efficiency. Reducing the core mass flow tends to increase the load on the LP turbine, so this unit may require additional stages to reduce the average stage loading and to maintain LP turbine efficiency. Reducing core flow also increases bypass ratio (5:1, or more, is now common).

Further improvements in core thermal efficiency can be achieved by raising the overall pressure ratio of the core. Improved blade aerodynamics reduces the number of extra compressor stages required. With multiple compressors (i.e. LPC, IPC, HPC) dramatic increases in overall pressure ratio have become possible. Variable geometry (i.e. stators) enable high pressure ratio compressors to work surge-free at all throttle settings.

The first high-bypass turbofan engine was the General Electric TF39, designed in mid 1960s to power the Lockheed C-5 Galaxy military transport aircraft. The civil General Electric CF6 engine used a derived design. Other high-bypass turbofans are the Pratt & Whitney JT9D, the three-shaft Rolls-Royce RB211 and the CFM International CFM56. More recent large high-bypass turbofans include the Pratt & Whitney PW4000, the three-shaft Rolls-Royce Trent, the General Electric GE90/GEnx and the GP7000, produced jointly by GE and P&W.

High-bypass turbofan engines are generally quieter than the earlier low bypass ratio civil engines. This is not so much due to the higher bypass ratio, as to the use of a low pressure ratio, single stage, fan, which significantly reduces specific thrust and, thereby, jet velocity. The combination of a higher overall pressure ratio and turbine inlet temperature improves thermal efficiency. This, together with a lower specific thrust (better propulsive efficiency), leads to a lower specific fuel consumption.

For reasons of fuel economy, and also of reduced noise, almost all of today's jet airliners are powered by high-bypass turbofans. Although modern combat aircraft tend to use low bypass ratio turbofans, military transport aircraft (e.g. C-17 ) mainly use high bypass ratio turbofans (or turboprops) for fuel efficiency.

Because of the implied low mean jet velocity, a high bypass ratio/low specific thrust turbofan has a high thrust lapse rate (with rising flight speed). Consequently the engine must be over-sized to give sufficient thrust during climb/cruise at high flight speeds (e.g. Mach 0.83). Because of the high thrust lapse rate, the static (i.e. Mach 0) thrust is consequently relatively high. This enables heavily laden, wide body aircraft to accelerate quickly during take-off and consequently lift-off within a reasonable runway length.

The turbofans on twin engined airliners are further over-sized to cope with losing one engine during take-off, which reduces the aircraft's net thrust by 50%. Modern twin engined airliners normally climb very steeply immediately after take-off. If one engine is lost, the climb-out is much shallower, but sufficient to clear obstacles in the flightpath.

The Soviet Union's engine technology was less advanced than the West's and its first wide-body aircraft, the Ilyushin Il-86, was powered by low-bypass engines. The Yakovlev Yak-42, a medium-range, rear-engined aircraft seating up to 120 passengers introduced in 1980 was the first Soviet aircraft to use high-bypass engines.